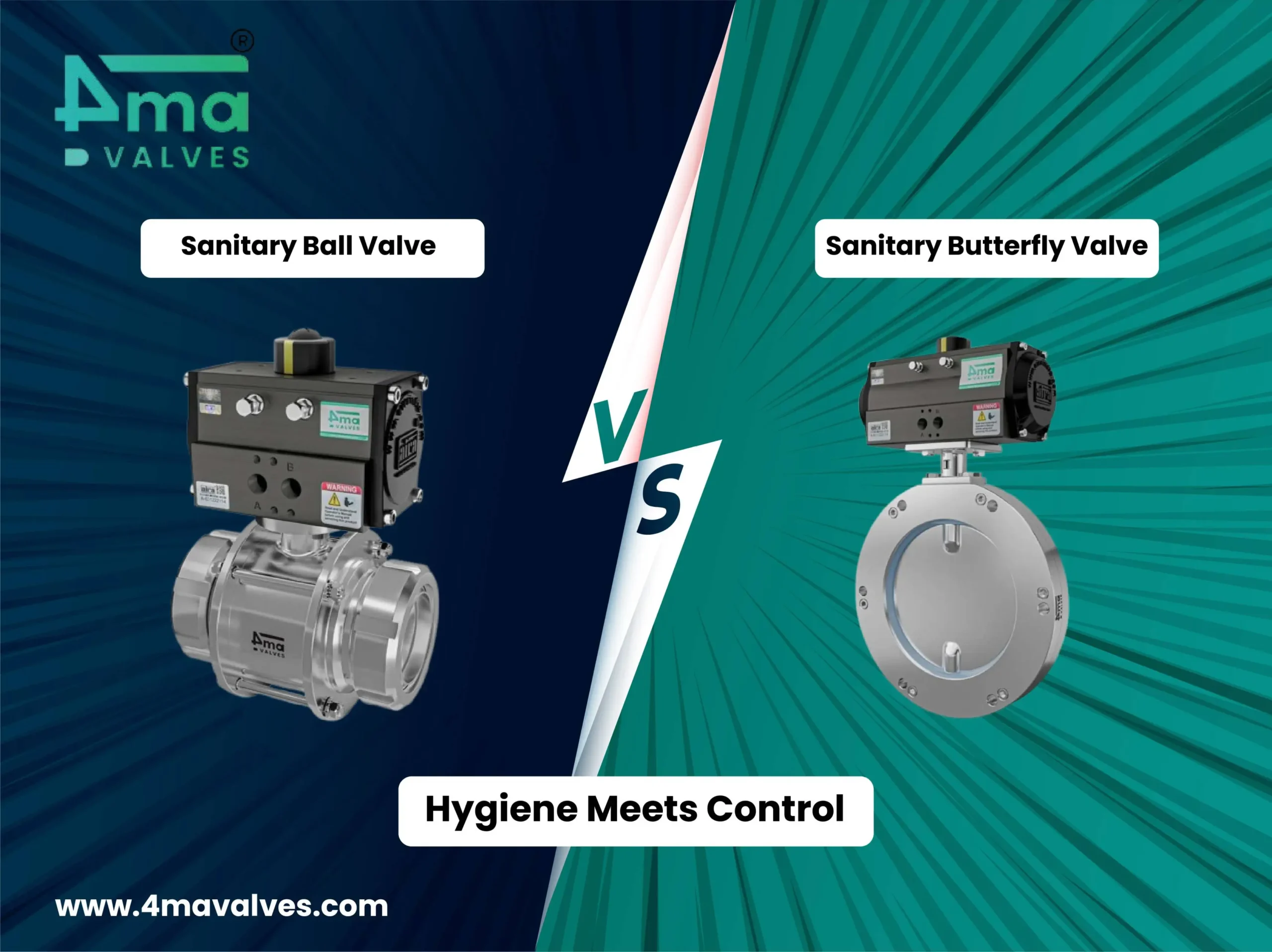

In industries where hygiene is critical, such as food and beverage, pharmaceuticals, dairy, cosmetics, and biotechnology, the quality and design of valves can directly impact product safety, regulatory compliance, and operational efficiency. Among the most commonly used options in sanitary process systems are sanitary ball valves and sanitary butterfly valves.

Both are designed with cleanliness, durability, and control in mind. However, their internal structures, flow characteristics, and applications differ significantly. Choosing the correct valve is not just about flow control, it’s about achieving the highest levels of sanitation and performance.

At 4ma Valves, we specialize in manufacturing top-quality sanitary valves that meet international hygienic standards and are trusted by industries worldwide. In this article, we will explore the key differences, advantages, and ideal use cases of sanitary ball valves and sanitary butterfly valves, helping you select the best option for your process.

What Are Sanitary Valves?

Sanitary valves are specifically designed to be used in processes where cleanliness and hygiene are of utmost importance. These valves are manufactured using food-grade materials, typically stainless steel 304 or 316L, and are polished to eliminate crevices that could trap bacteria or other contaminants. They are compatible with clean-in-place (CIP) and steam-in-place (SIP) procedures to ensure thorough cleaning and sterilization.

At 4ma Valves, our sanitary valves meet strict industry certifications such as 3-A, FDA, and EHEDG, making them ideal for hygienic fluid handling systems.

Sanitary Ball Valve: High Performance and Sealing Integrity

Design and Operation

A sanitary ball valve uses a solid, polished ball with a central hole that rotates inside the valve body to start or stop the flow of liquid. When the handle is turned 90 degrees, the hole aligns with the pipe, allowing full, unrestricted flow. Turning it again blocks the flow completely.

The ball design provides a full-bore flow path, ensuring zero flow restriction and making it suitable for applications involving viscous or particulate-laden fluids.

Key Features of Sanitary Ball Valves

- Excellent shut-off performance, ensuring no leakage

- Full port design, allowing maximum flow with minimal pressure drop

- Smooth internal surface, promoting easy cleaning and reducing contamination risks

- Available in manual, pneumatic, or electric actuation

- Robust and durable construction, ideal for high-pressure applications

At 4ma Valves, we manufacture sanitary ball valves using CNC-machined stainless steel with electropolished finishes. Our ball valves are designed to provide reliable operation and exceptional hygiene in demanding environments.

Sanitary Butterfly Valve: Simplicity and Cost Efficiency

Design and Operation

A sanitary butterfly valve consists of a round disc mounted on a rotating shaft. When the handle is turned, the disc rotates to open or close the valve. At a 90-degree angle, the disc is perpendicular to the flow and blocks it completely. When aligned with the pipeline, it allows flow to pass.

Unlike ball valves, butterfly valves do not have a full-bore opening, which can cause a slight pressure drop. However, their design is compact, lightweight, and highly economical.

Key Features of Sanitary Butterfly Valves

- Fast, quarter-turn operation for quick control

- Compact and lightweight, ideal for tight installations

- Fewer moving parts, resulting in lower maintenance

- Available in clamp, weld, or threaded end connections

- Cost-effective for large-diameter pipeline systems

At 4ma Valves, our sanitary butterfly valves are designed for easy disassembly, cleaning, and maintenance. We use high-grade elastomer seals and polished disc surfaces to ensure excellent sealing with minimal product adhesion.

Sanitary Ball Valve vs Sanitary Butterfly Valve: Head-to-Head Comparison

| Feature | Sanitary Ball Valve | Sanitary Butterfly Valve |

| Flow Control | Full bore, minimal pressure drop | Slight restriction due to disc in the flow path |

| Shut-off Integrity | Excellent, tight seal | Good, but may allow slight leakage under pressure |

| Cleaning | Easier with fewer product traps | Slightly more cleaning effort due to disc contact |

| Space Requirement | Bulkier, requires more space | Compact, ideal for tight piping layouts |

| Cost | Higher due to precision machining | More affordable |

| Maintenance | Requires occasional lubrication or seal replacement | Simple design, minimal maintenance |

| Ideal Applications | High-pressure, viscous fluids, sterile systems | General-purpose, low to medium pressure systems |

| Application | Easily automated | Easily automated |

Applications of Sanitary Ball and Butterfly Valves

Sanitary Ball Valve Applications

- Pharmaceutical and Biotech Processing:

Where sterility is critical, ball valves offer reliable sealing and full-bore flow for sterile water, buffer solutions, and injectable formulations.

- Dairy and Food Processing:

Ideal for handling milk, cream, honey, syrups, and other viscous products without clogging or shearing.

- Beverage Industry:

Used in beer, juice, wine, and soft drink production to maintain purity and prevent contamination.

Sanitary Butterfly Valve Applications

Water and Utility Lines in Sanitary Facilities:

Commonly used to regulate non-critical fluid flows like cleaning solutions and filtered water.

Cosmetics and Personal Care:

Useful for the production and transfer of liquid soaps, shampoos, and lotions where cost and ease of operation are priorities.

Breweries and Small Batch Processes:

Butterfly valves offer a practical and budget-friendly option for small to mid-sized flow systems.

At 4ma Valves, we offer both valve types in various sizes, pressure ratings, and end connections to meet your specific industry requirements.

Choosing the Right Valve for Your Sanitary System

Selecting between a sanitary ball valve and a sanitary butterfly valve depends on several factors:

Choose a Sanitary Ball Valve if:

- Your process involves high-pressure fluids or sterile applications

- You require zero leakage and full-bore flow

- You’re handling thick, viscous, or particulate-rich fluids

- Long-term durability and low maintenance are top priorities

Choose a Sanitary Butterfly Valve if:

- Your application is cost-sensitive

- You need a valve for on/off service in low-pressure systems

- Space is limited, and compact installation is essential

- The product is non-viscous, like water, juices, or mild cleaning agents

Still not sure? 4ma Valves offers expert consultation to help you evaluate your process parameters and recommend the ideal valve solution based on hygiene, flow control, and cost-efficiency.

Why 4ma Valves is the Preferred Choice for Sanitary Flow Solutions

4ma Valves is a leading manufacturer and exporter of sanitary valves, known for delivering high-performance products with precision craftsmanship. Here’s why industries across the globe trust us:

Superior Quality Materials: All valves are made using SS304 or SS316L stainless steel.

Customized Valve Solutions: Tailored to meet your exact process specifications

Certified Hygiene Compliance: Valves comply with FDA, 3A, and EHEDG standards

Innovative Engineering: Designed for CIP/SIP compatibility and easy maintenance

End-to-End Support: From design and selection to delivery and after-sales service

Whether you need a high-performance sanitary ball valve for a pharmaceutical plant or a budget-friendly butterfly valve for a dairy line, 4ma Valves has the technology, experience, and reliability you can trust.

Conclusion: Hygiene and Control, Perfectly Balanced

When it comes to sanitary processing, the right valve makes all the difference. Both sanitary ball valves and sanitary butterfly valves offer hygienic control, but each serves distinct applications. Ball valves are best for tight shut-off, high pressure, and demanding processes, while butterfly valves are preferred for economical and space-saving flow control.

At 4ma Valves, we take pride in engineering sanitary valves that combine flawless hygiene with superior performance. Our solutions are trusted by engineers, plant managers, and quality control teams across the food, pharma, and biotech sectors.