Industrial valves are essential additives in diverse sectors, which are pivotal in controlling the waft of fluids and gases within pipelines and equipment. From regulating water delivery in remedy vegetation to managing the difficult processes in pharmaceutical production, valves ensure operational performance and protection.

As a leading Industrial Valve Manufacturer in Ahmedabad, India, 4ma Valve is dedicated to delivering awesome solutions tailored to diverse industry needs.

Understanding Industrial Valves

An industrial valve is a solution that modulates the go with the flow and stress of fluids, gases, or slurries inside a gadget. By beginning, ultimate, or in part obstructing passageways, valves control the flow of materials, ensuring strategies run easily and thoroughly. Their programs several industries, inclusive of water treatment, power era, chemical processing, and meals and beverage production.

Types of Industrial Valves:

Selecting the best valve type is crucial for superior device performance. Here are a few common types:

1.) Ball Valves:

Featuring a round disc, ball valves provide reliable sealing and are ideal for packages requiring tight close-off. They are long-lasting, offer low glide resistance, and are suitable for structures in which brief starting and closing are important.

2.) Butterfly Valves:

Butterfly valves regulate flow using a rotating disc. Known for their compact layout and simplicity of operation, they are commonly used in large-scale water distribution, chemical offerings, and HVAC structures.

3.) Globe Valves:

Designed for specific flow control globe valves are outstanding for throttling purposes. They are extensively used in programs in which flow wishes to be regulated, including cooling and gasoline oil structures.

4.) Gate Valves:

Utilizing a sliding gate to block fluid float, gate valves are in general used for on-off control. They are suitable for applications requiring minimal pressure drop and bidirectional flow.

5.) Check Valves:

These valves save you backflow, making sure unidirectional float inside a system. They are vital in applications like refining, petrochemical, and water management structures.

Applications of Industrial Valves:

Industrial valves are essential for various applications:

Valves control water glide, manage stress, and ensure the secure handling of wastewater, playing a crucial position in municipal and commercial water treatment facilities.

Oil and Gas Industry:

In upstream, midstream, and downstream operations, valves manipulate the waft of crude oil, natural gasoline, and delicate merchandise, making sure safe and green transportation and processing.

Pharmaceutical Manufacturing:

Valves maintain sterile conditions and specifically manage overflow coping techniques, which are important for product quality and compliance with regulatory standards.

Food and Beverage Industry:

Valve systems manage the glide of elements and cleansing agents in processing and packaging strains, ensuring hygiene and stopping contamination.

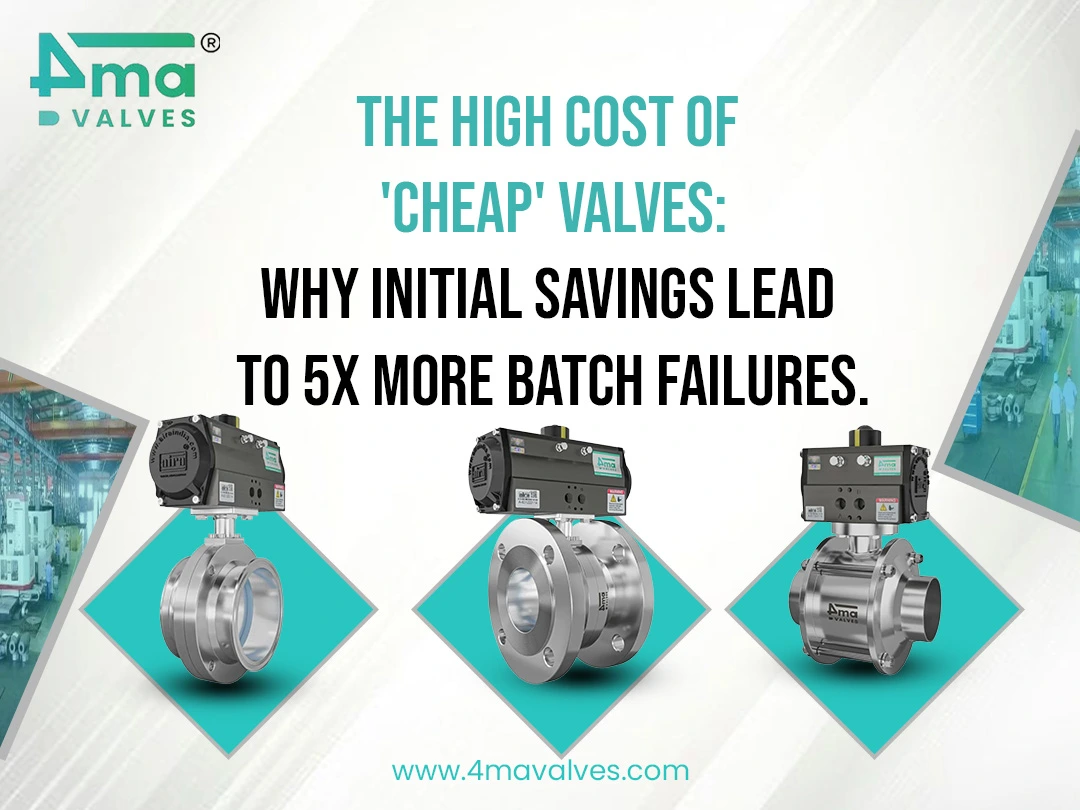

Benefits of High-Quality Industrial Valves:

Investing in superior industrial valves gives numerous advantages:

Enhanced Safety:

Reliable valves prevent leaks and spills, reducing the threat of accidents and environmental risks.

Operational Efficiency:

High-satisfactory valves ensure clean operation, minimizing downtime and maintenance expenses.

Longevity:

Durable valves resist harsh running conditions, presenting lengthy provider lifestyles and reducing the need for frequent replacements.

Regulatory Compliance:

In industries like pharmaceuticals and meal processing, valves that meet stringent standards assist in maintaining compliance with fitness and safety rules.

4ma Valve: Your Trusted Partner in Industrial Valves:

At 4ma Valve, we specialize in manufacturing high-quality valves to maintain critical applications in the pharmaceutical, cosmetic, dairy, food & beverage, and paint & color industries. With decades of experience in manufacturing both automated and manual valves exclusively from high-grade stainless steel.

Our product range includes:

Butterfly Valves are Ideal for applications requiring compact design and efficient flow control.

Ball Valves Offer reliable sealing and durability for various industrial processes.

Control Valve/ Safety Valves: Ensuring system safety by maintaining optimal pressure levels.

Pharma Diaphragm Valves are designed for handling corrosive media, providing excellent chemical resistance.

Segmented Type Bottom Valves are suitable for applications requiring minimal downtime and quick operation.

Angle Type Bottom Valves prevent backflow to maintain system integrity.

Valve Automation enhances process control with automated valve solutions.

Knife Gate Valves are designed for handling slurry and viscous fluids in demanding applications.

Our commitment to quality and innovation ensures that our valves offer high industry standards, by providing our customers with reliable solutions that enhance operational efficiency.

Conclusion

Understanding the various types of industrial valves and their applications is crucial for selecting the right solution for your specific needs. At 4ma Valve, we are dedicated to providing top-quality valves that offer exceptional performance, durability, and safety across various industries. Partner with us to experience the benefits of superior valve solutions tailored to your requirements.