Sanitary Control Valves play a crucial role in maintaining hygiene, performance, and precision in food processing, the pharmaceutical industry, and biotechnology industries. Ensuring long-time performance requires ordinary preservation, proper handling, and proper valve selection.

4ma Valves, India’s superior industrial valve manufacturer, offers the best quality sanitary control valves designed for durability and the most appropriate performance.

In this guide, we will get you through the excellent tricks for maintaining sanitary control valves to increase their working life and increase efficiency.

Importance of Maintaining Sanitary Control Valves

Sanitary control valves alter flow control, even as preventing corrosion and ensuring compliance with the application’s hygiene standards, overlooking upkeep can cause inefficiencies, product contamination, and pricey downtime. Proper maintenance helps:

- Extending the lifespan of the valves

- Improve operational performance

- Prevent leakage risks

- Reduce downtime and upkeep charges

- Maintain regulatory compliance

Best Practices for Maintaining Sanitary Control Valves

1.) Regular Inspection and Cleaning

Routine inspection is crucial to perceive put-on, damage, or infection buildup in sanitary control valves. Follow these steps for proper inspection and cleaning:

- Visual Inspection: Check for visible signs of wear, corrosion, or leaks.

- Internal Inspection: Disassemble the valve and study the seals, gaskets, and diaphragms.

- Cleaning: Use industry-authorised cleaning solutions to do away with particles and prevent bacterial growth. 4ma Valves sanitary control valves are designed for easy disassembly, ensuring thorough cleaning and reassembly.

2.) Lubrication of Moving Parts

Proper lubrication reduces friction and wear on valve components, ensuring easy operation. Use FDA-accepted lubricants that observe enterprise standards to save you from contamination. Avoid over-lubrication, as excess lubricant can cause dirt and particles.

3.) Monitor Valve Performance

Tracking valve performance can assist in detecting early signs of failure. Key overall performance indicators (KPIs) to screen consist of:

- Flow rate: Ensure the valve maintains the most efficient flow without pressure drops.

- Sealing performance: Check for any leaks or loss of pressure.

- Actuator functionality: Pneumatic or electric actuators need to function smoothly without delays.

4.) Preventive Maintenance Schedule

Implement a preventive upkeep production strategy primarily based on working conditions and valve usage frequency. Consider the following intervals:

- Weekly: Quick visible inspections and floor cleaning.

- Monthly: Internal cleaning and lubrication.

- Quarterly: Performance checking out and gasket substitute if necessary.

- Annually: Comprehensive disassembly, deep cleansing, and complete inspection.

5.) Proper Installation and Handling

Even the high-quality sanitary control valves require proper setup to function efficiently. Follow these set-up best practices:

- Ensure alignment with the pipeline go with the flow path.

- Use suitable fittings and avoid excessive pressure throughout tightening.

- Follow the producer’s tips for strain and temperature ratings.

4ma Valves present efficient control on valve installation to make certain highest quality performance.

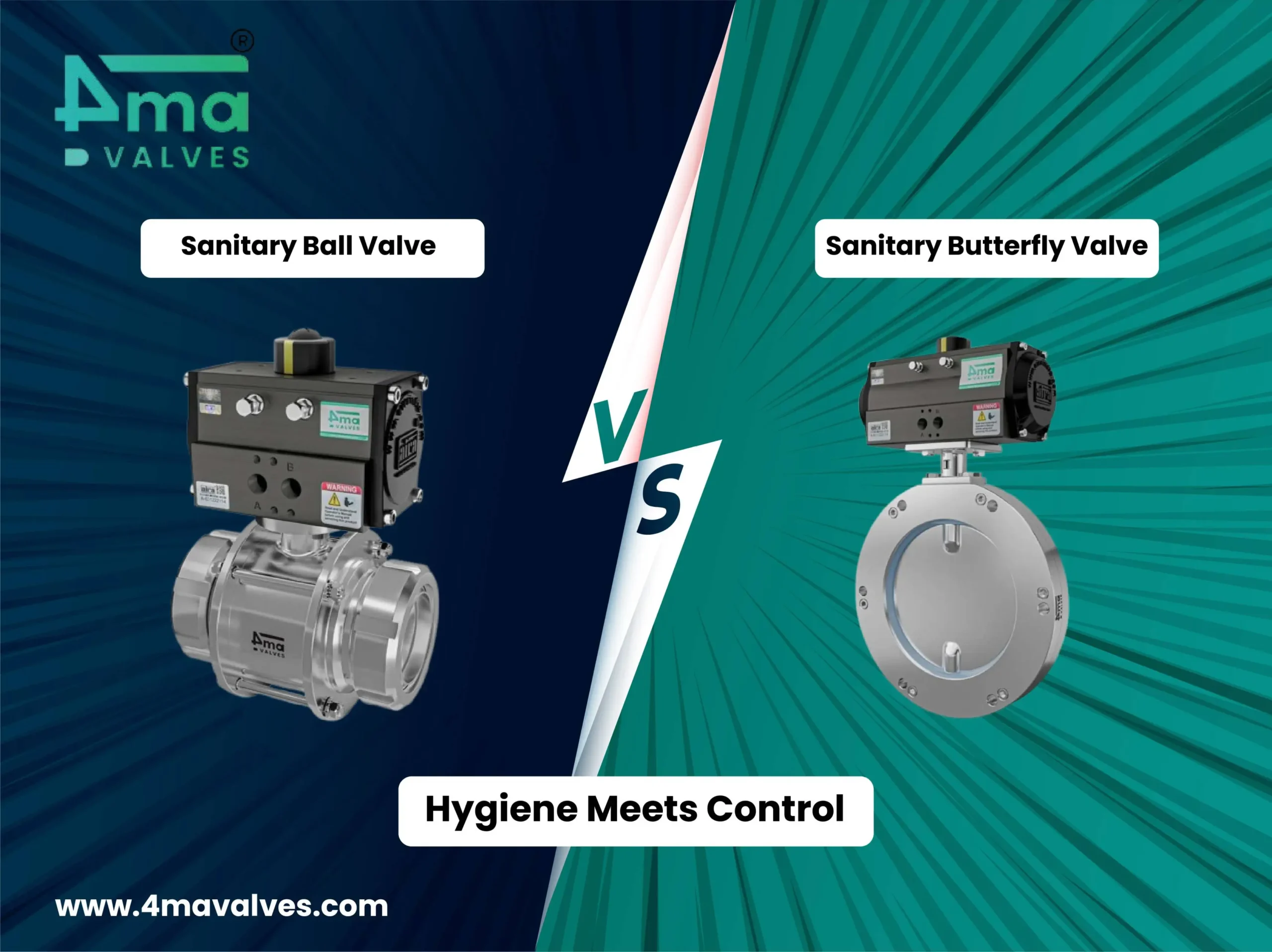

6.) Choose High-Quality Sanitary Control Valves

Selecting the right valve drastically impacts long-term overall performance and preservation efforts. 4ma Valves manufactures premium sanitary control valves designed for:

- Corrosion resistance: Made with chrome steel and FDA-permitted substances.

- Easy maintenance: Simple disassembly for cleansing and factor replacement

- High precision control: Reliable flow law for sensitive applications.

4ma Valves offers the best quality Sanitary Control Valve

4 ma Valves is a dependable call in the commercial valve industry, presenting pinnacle-tier sanitary control valves that meet worldwide standards. Our valves are designed for:

- Durability and long lifespan

- Superior hygiene and infection prevention

- Effortless preservation and cleansing

- Optimized flow control for various industries

When you select 4ma Valves, you invest in the best, reliability, and expert assistance to improve your industrial procedures.

Conclusion

Maintaining sanitary control valves is critical to ensure efficiency, hygiene, and long-term reliability in crucial industries. By following ordinary guidance, cleaning, lubrication, and preventive maintenance schedules, you can increase the lifespan of your valves and reduce operational downtime.

4ma Valves is dedicated to offering high-performance sanitary control valves that supply excellent, exceptional reliability. Contact us to explore the high-quality valve solution for your needs and enhance your application’s performance.